Cooling towers are an essential part of many industries, as they are commonly used in HVAC systems and industrial and power generation plants. However, these towers require proper maintenance to function efficiently. Maintenance of a cooling tower involves keeping it clean and addressing any defects that may develop over time. If left untreated, such defects can cause your cooling tower to fail, leading to costly repairs and downtimes. In this blog post, we'll discuss the purpose of a cooling tower, list 5 common repairs that your cooling tower may need, and outline the essential steps to maintaing a cooling tower.

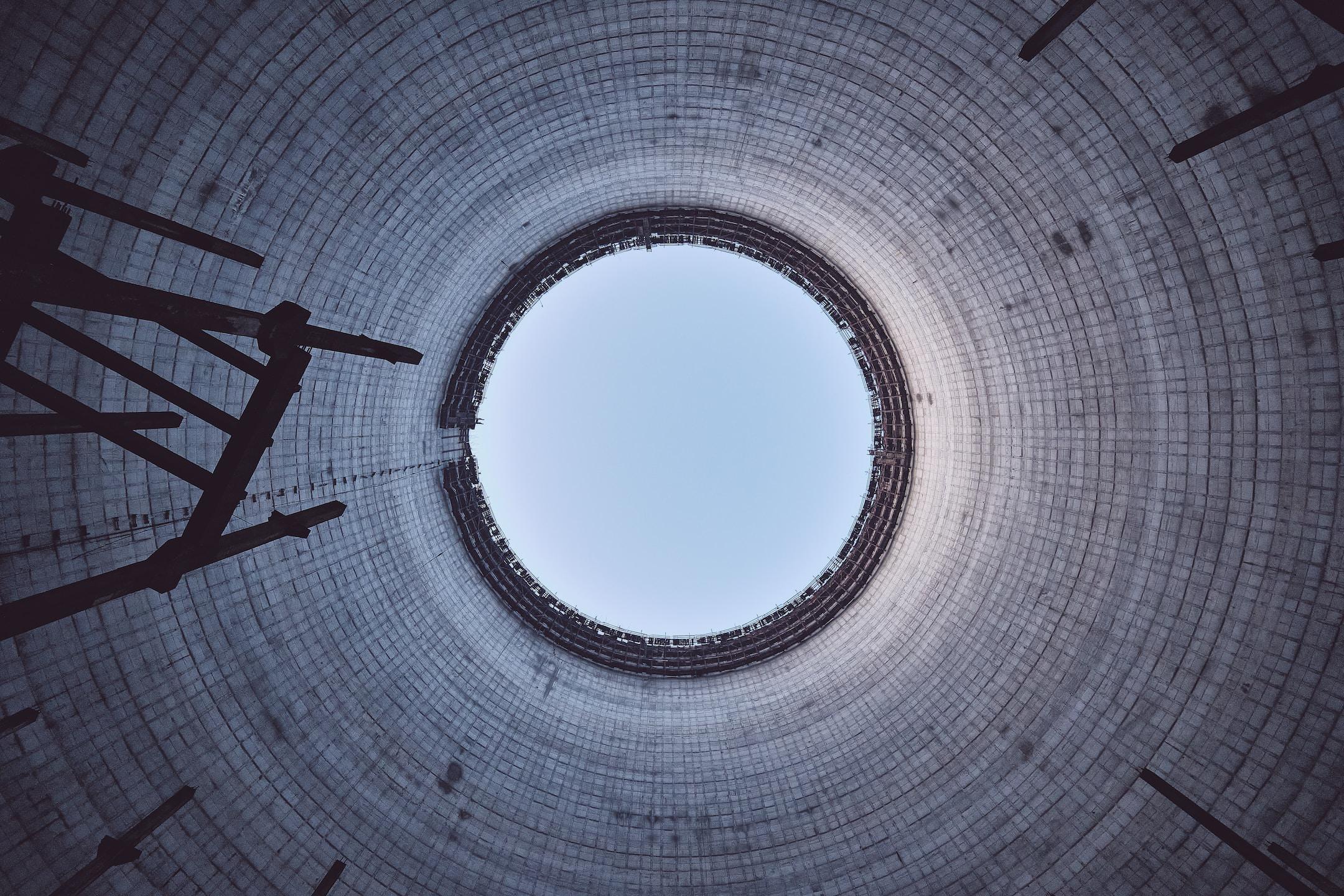

Cooling towers function by transferring heat from water-cooled equipment to the atmosphere. This process cools the water, which is then reused in the cooling system. Cooling towers consist of three parts, namely the basin, the tower itself, and the components that direct the flow of water through the tower. Most cooling towers rely on fans to increase the airflow and cool the water. Depending on the type of cooling tower, they can operate as crossflow, counterflow, or hybrid models.

Corroded or Clogged Scale Piping

Corrosion can occur in the water pipes and tower walls during the cooling process, which can cause leaks. Scale and debris built-up in the system will decrease the flow rate and negatively impact cooling capacity, which can lead to system failure.

Motor Failure

Motor failure is a common problem that can cause your cooling tower to shut down. Motors can fail due to normal wear and tear, lack of maintenance, or electrical issues.

Fan Malfunction

The fan is responsible for moving the air and cooling the water, and when it malfunctions, it can cause the tower to overheat. Common fan problems include motor failure, blade wear, and imbalance.

Water Treatment Issues

Cooling towers use large quantities of water that can lead to mineral buildup, bacterial growth, and corrosion, which can impair proper function. Regular cleaning and water treatment can minimize the risk of such issues.

Unbalanced Flow

Cooling towers operate at optimal efficiency when water flows through them evenly. An imbalance in water flow can occur for to various reasons including clogged nozzles, leaks, and improper pipe fitting.

The following nine steps are critical to ensure proper cooling tower maintenance:

a. Establish a maintenance schedule that follows the recommended intervals based on the type of cooling tower.

b. Regularly inspect the tower for signs of wear, tear, and mineral deposits.

c. Ensure proper water treatment measures are in place, including monitoring, testing, and chemical dosing.

d. Regularly check the cooling tower's structural components, including framing, fans, and motors.

e. Clean the tower basin, spray nozzles, and the cooling tower fill regularly.

f. Clean and test the sump strainer.

g. Conduct thorough winter shutdown procedures to prevent pipe damage.

h. Replace any damaged or missing parts, such as drift eliminators, baffles, and fill.

i. Ensure proper record-keeping to track maintenance, repairs, and modifications to the cooling tower system.

Regular maintenance and repairs are critical to the longevity of your cooling tower system. Skipping essential maintenance steps or failing to repair defects can cause equipment failure and costly downtime. By following a regular maintenance schedule and staying ahead of repairs, you can keep your cooling tower system running at optimal efficiency and avoid unexpected expenses. If you see even the slightest signs of damage in your system, address it as soon as possible to avoid any exacerbation of the damage.

Caldwell Mechanical is the ideal choice for cooling tower service and maintenance. We are committed to providing dependable, expert services for any repairs your cooling tower may require. We prouldy guarantee that when you choose Caldwell Mechanical, you are choosing professionalism, experience, and mechanical know-how. Get in touch with us today to learm more about our cooling tower services.